Due to their complex forging process, exposure to battle damage, and centuries of aging, samurai swords often exhibit a variety of flaws. While minor defects that do not affect performance are usu...

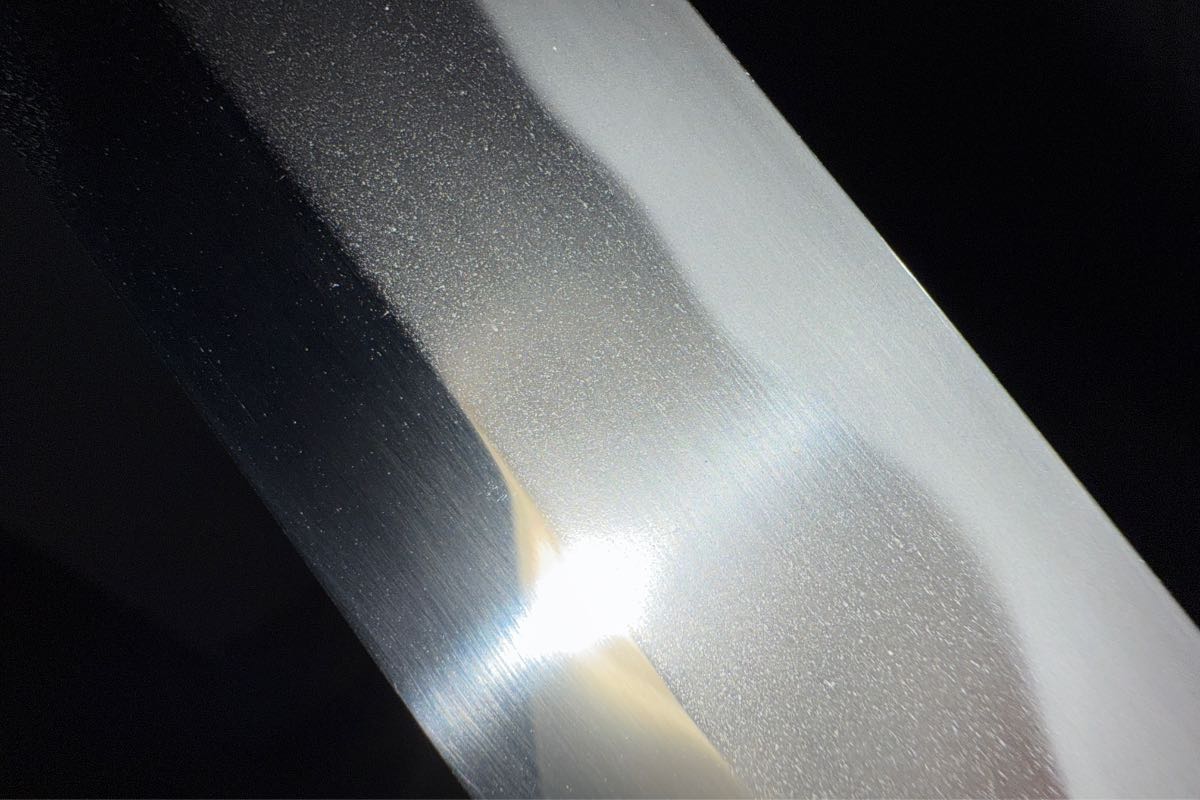

Discover how the quenching process creates the stunning beauty of nioi and nie in Japanese swords. Learn about rare features like sunagashi, kinsuji, utsuri, and the hidden secrets of traditional f...

Discover the intricate craftsmanship behind Japanese sword polishing and tameshigiri test cutting. Learn how master polishers reveal the hamon’s hidden beauty.

Tamahagane, the legendary steel behind authentic Japanese katanas, is forged through a centuries-old tradition using iron sand and charcoal. Discover the intricate smelting process inside the ancie...

Once the blade is formed, the quenching process begins to achieve a sharp and hardened edge, during which the pattern on the blade surface is created. The efforts involved in this phase are more co...

The tsuka, or handle of a sword, plays a vital role in its functionality and aesthetics. A well-designed handle must offer a comfortable grip, ensuring that it is neither too thick nor too thin. Th...

The quenching process, particularly the clay tempering method, is one of the most crucial steps in the making of a traditional Japanese katana. This stage, known as yaki-ire in Japanese, is where t...

Nakago The ‘nakago’ is also known as the ‘tang’ and is the most informative part of a Japanese sword during its evaluation, with its importance rivaling that of the blade itself. When appreciating...

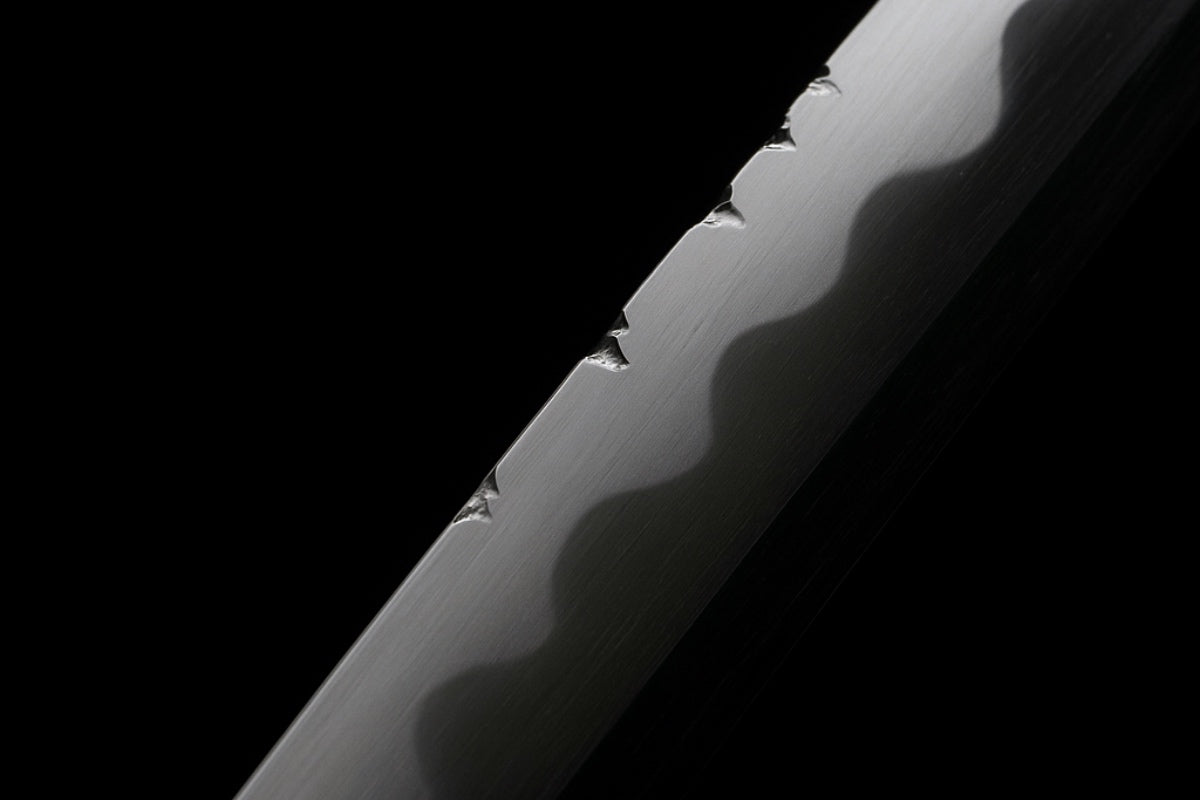

Hamon Through repeated mixing, folding, and forging, before quenching, a layer of clay is applied to the blade, leaving only the edge exposed. This allows the edge to directly contact the water dur...